Wizz.com - Flash Report

Integrated Steel Mills

The primary use of Iron Ore is in the production of steel.

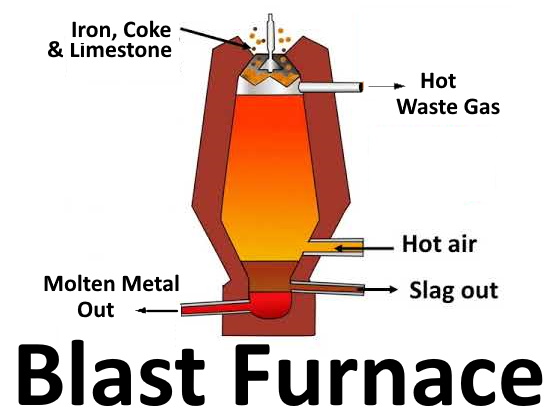

In the Integrated Steel Mill process

Iron Ore

is blended with

Limestone

and

Metallurgical Coking Coal

in a blast furnace to produce molton steel or

Pig Iron.

The hot metal is typically formed into a

Steel Billet

as an intermediate step prior to conversion into various steel products such as

Sheet, Plate, Rod & Bar.

The addition of

Mill Prepared Steel Scrap

into the integrated process improves the economics, efficiency and yield of the steel output.

Blast Furnace Slag (BFS)

The primary By-Product generated from Integrated Steel Mills is

Blast Furnace Slag (BFS).

One common use of BFS is as an

Aggregate

or direct replacement for natural stone gravel.

An alternative use of BFS is as feedstock for the

Cement

industry.

Blast furnace slags are also used to produce mineral wools and

insulation

products.

Mill Scale

The oxidized surface scale residue generated at the rolling mill when processing Steel Billet.

The

Mill scale

by-product may be recirculated back into the primary blast furnace cycle.

Green Steel

The production of steel with a reduced carbon footprint is referred to as Green Steel.

The roasting of

Coal

in coke ovens to produce MET COKE are a source which releases large amounts of CO2 emissions.

Capturing these emissions could harness untapped energy.

The use of

Renewable Natural Gas (RNG)

or

Green Hydrogen

replaces traditional fossil fuels and results in the reduction of the carbon footprint.

The reduction of iron oxide (iron ore) using a

REDOX Displacement

Reaction may be one method of carbon free iron production.

Industrial Product & Commodity Trade

Cooksmill NetSystems operates an online

network

of exchanges that promote the trade of industrial products and commodities.

You may buy or sell any of the materials listed on this page by clicking on

the links and adding your trade inquiry.

The on-line exchange service directly connects Buyers and Sellers.

If we can assist you in any way in using the websites within the Cooksmill NetSystems

network,

please contact us at your convenience.

Please remember that you are responsible to perform your own due diligence on any prospective counter party

that you deal with and please

report

any abuse of our system.

Content on this page was produced for the benefit of

members

of the Cookmill NetSystem network.